4 Key Factors to Help Achieve Quick Turnaround PCB Assembly4 Key Factors to Help Achieve Quick Turnaround PCB Assembly

2023-3-22

4 Key Factors to Help Achieve Quick Turnaround PCB Assembly

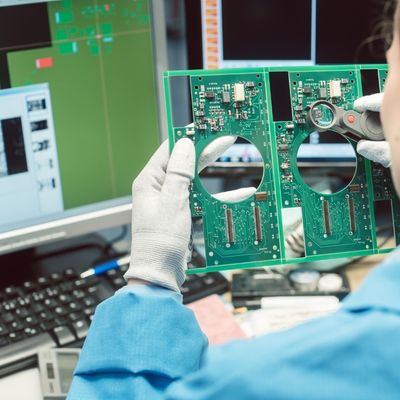

The quick turn PCB assembly provider usually reviews the bill of materials (BOM) and the design output like Gerber files before sending the quote for assembly. Once the quote is approved, prototype boards are fabricated and the parts are assembled. These prototype boards are tested for functional validation. After finalizing the prototype, the bulk production begins…

5 PCBA Procurement Tips From Qtech Technology

2023-3-14

When your company is developing electronic products you cannot skimp on quality. In your vendor selection process it is of the utmost concern.

You need to find PCB fabrication and assembly vendors that will give you the quality you demand. But at the same time, you need to find ways to reduce the overall cost of your project…

Why Surface Mount Technology for PCB Assembly is Preferred over Other Options

2023-3-14

Gradual evolution of printed circuit boards has made PCBs a critical, efficient, and compact component of a wide gamut of automobiles, machines and devices, computing terminals and other electronics. The introduction of PCBs has also contributed to certain technological developments and inventions in the global electronics industry. The ability of PCBs to connect a single electronic component with the electronics designs in order to render functionality to the entire setting is undeniable. There are several different technique used to assemble PCBs and Surface Mount Technology (SMT) is considered the most preferred of them all…

Learn About Different Types of PCBs and Their Advantages

2023-3-24

A printed circuit board (PCB) is a thin board made from fiberglass, composite epoxy, or other laminate materials. PCBs are found in various electrical and electronic components such as beepers, radios, radars, computer systems, etc. Different types of PCBs are used based on the applications. What are the various types of PCBs?

How dAdding Acrylic Conformal Coating to Your Printed Circuit Boards

2023-3-27

Acrylic resins (AR) are single component materials. To specify, they are preformed acrylic polymers that are dissolved in a solvent to be applied to surfaces. One main benefit of using an Acrylic conformal coating service on your electronics is it provides an excellent barrier to moisture/humidity and have good fungus resistance. They also have minimal chemical resistance which makes it ideal for reworking and removability.

Role of Functional Testing in PCB Assembly

2023-3-15

Printed circuit boards (PCBs) have significantly surged the growth of the electronics industry for many years, and this trend is set to continue for the next few years. They are the backbone of several electrical, electronics, or electromechanical devices. Advancements in electronics and technology have led PCBs to their way in several critical applications. PCB design, fabrication, and assembly are all important aspects of the process, and it is crucial to have no errors in these stages. Also, it is crucial to meet the functional requirements based on the application and check how it works for the final product. This is why PCBs undergo different testing and inspection methods during each step of the manufacturing process. There are different PCB testing and inspection methods used today, and they may be used at different levels or stages. Of all these, functional testing is a popular testing technique that guarantees the functionality of circuit boards. Although it comes at a much later stage, it is extremely important as a functional test verifies the component’s functionality, parametric values, and other important aspects of circuit boards in detail. Functional testing is done close to the real environment and tested with the actual product. Are you intrigued to know more about the PCB functional test?

Classification of PCB by IPC and its advantages

2023-3-28

IPC standards are made to regulate the functionality of PCB. The Institute of printed circuit boards (IPC) is a worldwide association that is developed for PCB-concerned standards. IPC has developed more than 300 functional standards which are being followed worldwide by all PCB companies. IPC categorizes PCB into three different classes 1, 2, and 3. These classes are based on the quality of production levels such as design, assembly, components, packaging, etc. IPC standards define the quality level of production and functionality of PCB.